There is no simple formula or rule that can be followed in selecting the proper casters. Many varying and individual factors must be balanced to make the selection that will do the best job for you. The following are several of the more important considerations.

Load Weight. The heavier the load, the larger the wheel required for the caster. The weight of the load also influences the mobility of the wheel. Roller or ball bearings are recommended for loads over 400 pounds. Every caster has a defined load capacity.

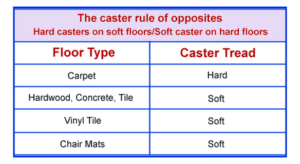

Floor Conditions. Make sure the wheel you select is large enough to pass over cracks in the floor, tracks, moldings and other obstructions. For floor protection on linoleum, tile, carpet, etc., use polyurethane or soft rubber wheels.

Unusual Conditions. Each wheel material has certain characteristics which will give the best results where unusual conditions exist. For example, where acids, oils, chemicals and other conditions harmful to rubber are present, polyurethane, polyolefin, phenolic or steel wheels are recommended. Check conditions, then select your caster and wheel.

Rolling Ease. The larger the wheel diameter, the easier it rolls. Roller bearings carry heavier loads. Ball bearings roll easier but carry lesser loads. When possible, use the largest ball bearing wheel for best results.